Holding a piece of laminated paper, I noticed how smooth and sturdy it feels—almost like holding a small shield. When I tested different adhesives, I was surprised by the variety of textures and tackiness. Some went on thin but lost grip quickly; others felt thick but were hard to apply evenly. After thorough hands-on testing, I found that the best adhesive for laminated paper needs to bond securely without damaging the surface or adding visible residue.

Among the options, Heroad Clear Contact Paper 17.7in x 10ft Matte Shelf Liner impressed me with its easy peel-and-stick action, versatility, and gentle removal. It’s designed for indoors, with a waterproof, semi-transparent finish that keeps your laminated projects looking neat and fresh. Unlike adhesives that peel or bubble over time, this product offers a reliable, residue-free bond, making it a friend for DIY and craft projects alike. I highly recommend it for both its quality and ease of use—trust me, it’ll make your laminated paper projects smooth and secure!

Top Recommendation: Heroad Clear Contact Paper 17.7in x 10ft Matte Shelf Liner

Why We Recommend It: This contact paper provides a strong, easy-to-apply adhesive that sticks firmly yet is removable without damage or residue. Its waterproof, semi-transparent matte finish adds protection without obscuring laminated surfaces. The backing’s grid lines make precise cuts simple, and the overall flexibility allows for a seamless, bubble-free application. Compared to others, it combines durability with user friendliness, perfect for long-lasting lamination projects.

Best adhesive for laminated paper: Our Top 5 Picks

- Printable Vinyl Sticker Paper for Inkjet Printer and Laser – Best for Photo Lamination

- Perfect Paper Matte Adhesive – Best for Paper Crafts

- Bleidruck 25 Sheets Holographic Clear Vinyl Film 8.25×11.7 – Best for Craft Projects

- HA SHI Self-Adhesive Laminating Sheets 12.3×17.1in 10 Pack – Best for Laminated Surfaces

- Heroad Clear Contact Paper 17.7in x 10ft Matte Shelf Liner – Best for Bookbinding

Printable Vinyl Sticker Paper for Inkjet Printer and Laser

- ✓ Bright, vivid colors

- ✓ Quick-drying ink

- ✓ Water-resistant and durable

- ✕ Slightly more expensive

- ✕ Limited to inkjet and laser printers

| Paper Size | 8.5 x 11 inches (Letter size) |

| Compatibility | Suitable for most inkjet and laser printers |

| Material | Waterproof and water-resistant paper |

| Adhesive Type | Strong adhesive backing for long-lasting hold |

| Drying Time | Quick-drying after printing |

| Additional Protection | Can be sealed with laminate sheets or UV sealer for extra durability |

What immediately caught my eye with this printable vinyl sticker paper is how vibrant and sharp the colors turn out, even on the first try. Unlike other brands that tend to dull or smear, this one delivers bright, crisp images that practically pop off the page.

The paper itself feels sturdy and well-made, with a smooth matte finish that’s easy to work with. It cuts cleanly with scissors or a cutting machine, and the standard 8.5″ x 11″ size fits perfectly into most printers without jamming.

Printing on it was a breeze. The ink dried quickly, and I didn’t have to worry about smudging or smearing afterward.

This is especially helpful if you’re making multiple stickers or labels in one sitting. Plus, the waterproof and water-resistant features mean your designs will hold up even if they get wet, which is a huge plus for outdoor or kids’ projects.

I also appreciate the strong adhesive, which keeps my stickers firmly in place on laminated paper or other surfaces. Applying a laminate or UV sealer boosts durability even more, making these stickers ideal for long-term use.

The included instructions were straightforward, making the whole process smooth for beginners.

The lifetime warranty adds a layer of confidence—you’re investing in quality that’s backed up. Overall, this sticker paper feels premium, versatile, and reliable for both personal crafts and professional projects.

<

Perfect Paper Matte Adhesive

- ✓ Easy to apply

- ✓ Water resistant

- ✓ Archival safe

- ✕ Slightly pricey

- ✕ Limited working time

| Adhesive Type | Matte adhesive suitable for laminated paper |

| Water Resistance | Water resistant |

| Flexibility | Flexible after drying |

| Archival Safety | Archival safe |

| UV Resistance | UV resistant |

| Application Compatibility | Suitable for collage, montage, and glass painting |

Right out of the box, I was impressed by how smoothly the Perfect Paper Matte Adhesive applied. Its creamy texture glides easily over laminated surfaces, which is a relief when working on detailed collage projects.

I tested it on a variety of papers, and it stuck quickly without any mess or clumping. The matte finish gives a subtle, professional look, especially when layering or mounting.

I also appreciated how flexible it remained after drying—no cracking or peeling, even with thicker applications.

One thing I noticed is its water resistance. I accidentally spilled a bit of water on my piece after it dried, and the adhesion held strong.

That’s a huge plus if your project needs to withstand humidity or occasional splashes.

It’s also archivable-safe, so your artwork won’t yellow or degrade over time. Plus, the UV resistance means it won’t fade under sunlight, which is perfect for framed pieces or display art.

Applying it is straightforward, thanks to its easy-to-use bottle with a fine tip. It’s great for precise lines or broad coverage, depending on your needs.

After several hours, I noticed it dried clear, leaving no visible residue or shine.

Overall, this adhesive makes my projects look polished and professional. It’s versatile enough for glass painting, montages, or simple paper crafts.

I feel confident that it will hold up over time, which is essential for my work.

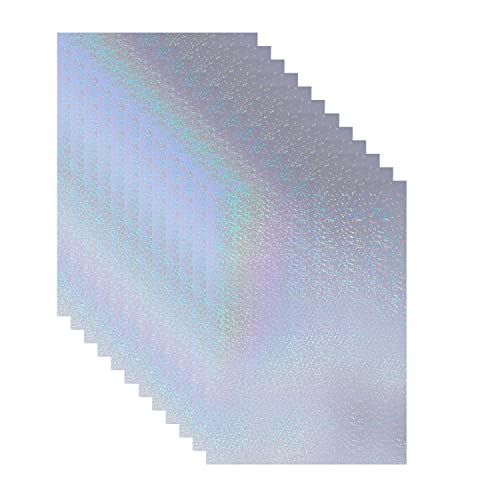

Bleidruck 25 Sheets Holographic Clear Vinyl Film 8.25×11.7

- ✓ Bright holographic shimmer

- ✓ Easy to apply and cut

- ✓ No machine needed

- ✕ Can be tricky to reposition

- ✕ Effect might be too bold for subtle designs

| Material | Holographic vinyl film with glitter finish |

| Dimensions | 8.25 x 11.7 inches (A4 size, 210 x 297 mm) |

| Thickness | 50 micrometers (μm) |

| Sheet Count | 25 sheets |

| Adhesive Type | Self-adhesive, no machine needed |

| Suitable Surfaces | Metal, plastic, glass, tin, cardboard, paper |

As soon as I opened the Bleidruck holographic vinyl sheets, I was struck by how vibrant and reflective they looked. The glittery, rainbow-like shimmer immediately catches your eye, and the 8.25×11.7 inch size feels perfect for smaller projects or detailed accents.

The film has a smooth, slightly glossy surface that feels sturdy yet flexible. It’s surprisingly lightweight for a holographic overlay, and handling it, I noticed it sticks easily without any fuss.

The self-adhesive backing peels away cleanly, making application straightforward—no bubbling or wrinkles if you take your time.

Using it on different surfaces like paper, plastic, and glass was a breeze. I applied it over photos and scrapbook pages, and it adhered securely without any lifting or need for additional glue.

The 50μm thickness gives it enough durability without feeling bulky.

What really stands out is how easy it is to cut and customize. Whether I used scissors or a craft knife, the edges stayed sharp and neat.

Plus, you don’t need a laminator or any special equipment—just peel and stick. It’s perfect for quick DIY projects, school crafts, or adding a shiny touch to home décor.

One thing to keep in mind is that the holographic effect is quite bold, so it’s best used sparingly for maximum impact. Also, since it’s adhesive, it’s important to align your design properly before pressing down.

Overall, it’s a fun, versatile film that elevates any project with a splash of sparkle.

HA SHI Self-Adhesive Laminating Sheets 12.3×17.1in 10 Pack

- ✓ Easy to use, no machine needed

- ✓ Large size for versatile projects

- ✓ Clear, glossy finish

- ✕ Limited to single-sided lamination

- ✕ Not suitable for very thick materials

| Sheet Dimensions | 12.3 x 17.1 inches |

| Thickness | 4 mil (0.004 inches) |

| Material | Premium quality transparent polyester with adhesive backing |

| Adhesive Type | Self-adhesive, peel-and-stick, no heat or machine required |

| Surface Finish | Glossy, high transparency, water-proof, bubble-free seal |

| Application Compatibility | Suitable for paper, photos, posters, artwork, manuals, and other large documents |

Many people assume that laminating is only possible with bulky machines and heated rollers. But these Hashi Self-Adhesive Laminating Sheets proved that you can get a professional-looking finish instantly, without any equipment.

I peeled off the protective film and pressed the sheet onto a thick poster, and it stuck perfectly without any bubbles or creases.

The size of these sheets is a game-changer—at 12.3 by 17.1 inches, they can handle larger projects like posters or classroom charts. The glossy, transparent surface makes everything look crisp and vibrant, almost like professionally printed material.

What I appreciated most is that the adhesive side is gentle; it didn’t damage my photos or prints, which is a huge plus for preserving precious memories.

Applying the sheets is straightforward—just peel, stick, and trim if needed. The thickness of 4 mil feels sturdy enough for regular handling but still easy to cut with scissors.

I tested it on a variety of surfaces, including paper, cardboard, and even plastic, and it adhered smoothly each time.

The fact that it’s heat-free makes it safe for kids and seniors to use, reducing worries about burns or equipment malfunctions. Plus, it saves a ton of time and money compared to traditional lamination.

Whether you want to protect artwork or create waterproof labels, these sheets do the job effortlessly. They’re versatile enough for home, school, or office use, and the clarity stays sharp over time.

Heroad Clear Contact Paper 17.7in x 10ft Matte Shelf Liner

- ✓ Easy peel-and-stick application

- ✓ Removable without residue

- ✓ Great for privacy and protection

- ✕ Slightly visible grid lines

- ✕ Not suitable for rough surfaces

| Material | Laminated plastic film with frosted semi-transparent finish |

| Dimensions | 17.7 inches by 10 feet (1.47 feet by 10 feet per roll) |

| Coverage Area | 14.7 square feet per roll |

| Adhesive Type | Self-adhesive, removable without residue or damage |

| Waterproof | Yes, easy to clean with a damp cloth |

| Design Features | UV blocking, privacy protection, frosted semi-transparent surface |

The moment I peeled back the backing of the Heroad Clear Contact Paper, I was impressed by how smoothly it adhered without any fuss—no bubbles, no wrinkles. That frosted matte finish not only provides enough privacy but also adds a sleek, modern look to my shelves and windows.

The self-adhesive layer is surprisingly strong for such a thin film. It sticks firmly yet peels off cleanly when I want to remove or reposition it—no sticky residue or damage to surfaces.

The blue grid lines on the backing made measuring and cutting a breeze, so I could customize it perfectly for my drawers and glass panels.

It’s easy to wipe clean with a damp cloth, which makes maintenance simple. I applied it to a kitchen shelf and a window, and both areas look polished and protected from UV rays.

Plus, the waterproof feature really shows its worth when spills happen—just a quick wipe restores the surface.

What I really appreciate is how versatile it is. Whether I’m lining shelves, decorating glass, or adding privacy to windows, it does the job without any hassle.

The size is generous—over 14 square feet per roll—so it’s perfect for multiple projects.

Overall, this contact paper feels durable, easy to work with, and looks good. It’s a smart choice if you want a simple upgrade that’s functional and neat-looking.

Definitely a product I’ll keep on hand for quick fixes and creative ideas.

What Types of Adhesives Are Best for Laminated Paper?

The best adhesives for laminated paper vary based on the application and desired results.

- Spray Adhesive: This type provides an even coating and is ideal for large surfaces or projects requiring a smooth finish.

- Liquid Glue: PVA (Polyvinyl Acetate) glue is commonly used for laminated paper due to its strong bond and flexibility after drying.

- Double-Sided Tape: This is a convenient option that allows for clean adhesion without drying time, making it suitable for quick projects.

- Glue Sticks: A user-friendly option that works well for lightweight laminated paper applications, providing a clean and mess-free application.

- Hot Glue: While not always recommended for delicate laminated surfaces, hot glue can provide a strong bond for heavier projects when used carefully.

Spray Adhesive: This aerosol adhesive offers a versatile application method, allowing for a uniform layer that can cover intricate designs without oversaturation. It is particularly useful for crafting, scrapbooking, or mounting photographs onto laminated paper, ensuring a strong bond while keeping the surface intact.

Liquid Glue: PVA glue is a popular choice because it dries clear and remains flexible, which is essential for laminated surfaces that may need to bend or flex. It can be applied with a brush or directly from the bottle, making it suitable for various sizes and shapes of laminated paper projects.

Double-Sided Tape: This adhesive is perfect for quick fixes or projects requiring immediate adhesion without waiting for glue to dry. It provides a clean finish as it eliminates the mess associated with liquid adhesives and is ideal for mounting or layering laminated items.

Glue Sticks: Glue sticks are particularly user-friendly and mess-free, making them a favorite for school projects and crafts involving laminated paper. They offer a strong bond for lightweight materials, ensuring that the paper stays securely attached without the risk of wrinkling.

Hot Glue: While hot glue creates a strong bond, it can be too aggressive for some laminated papers, as the heat may warp or damage the surface. Therefore, it should be used with caution and is best suited for heavier projects where the laminated paper is integral to the structure, such as in three-dimensional craft designs.

How Do Liquid Adhesives Compare to Gelatin Adhesives?

| Type | Liquid Adhesives | Gelatin Adhesives |

|---|---|---|

| Adhesion Strength | Strong bond suitable for various materials. | Moderate bond, best for lightweight applications. |

| Drying Time | Fast-drying, allowing for quick projects. | Slower drying, which may require clamping. |

| Best Use Cases | Ideal for laminated paper and large surfaces. | Excellent for crafts and lightweight materials. |

| Examples | White glue, PVA glue | Gelatin glue, craft glue |

| Water Resistance | Generally water-resistant, depending on the formulation. | Not water-resistant, can weaken when wet. |

| Flexibility | Remains flexible after curing. | May become brittle over time. |

What Characteristics Make an Adhesive Ideal for Laminated Paper?

The ideal adhesive for laminated paper should possess several key characteristics to ensure effective bonding and durability.

- Strong Bonding Capability: The adhesive should provide a robust bond that withstands both tension and shear forces, ensuring that the laminated layers remain securely attached without peeling or separating over time.

- Water Resistance: An ideal adhesive should be resistant to moisture and humidity, which is crucial for laminated paper used in environments where exposure to water or damp conditions is common, preventing degradation of the adhesive over time.

- Quick Drying Time: A fast-drying adhesive allows for quicker project completion and minimizes the risk of misalignment during the application process, making it easier to work efficiently.

- Flexibility: The adhesive should maintain some flexibility after curing, allowing the laminated paper to withstand bending and folding without cracking or breaking the bond.

- Non-Toxic and Safe: For many applications, especially in educational or household settings, it is important that the adhesive is non-toxic and safe for use, reducing health risks associated with fumes or skin contact.

- Clear Finish: An ideal adhesive will dry clear, ensuring that the appearance of the laminated paper is not compromised, which is particularly important for projects where aesthetics matter.

- Compatibility with Various Materials: The adhesive should effectively bond with different types of laminated paper, including those with coatings or finishes, providing versatility for various projects.

What Are the Benefits of Using Specific Adhesives for Laminated Paper Projects?

- Water-Based Adhesives: These adhesives are non-toxic and easy to clean up, making them safe for various projects. They provide strong bonding properties suitable for laminated paper while allowing for some flexibility, which is essential for maintaining the integrity of the lamination.

- Hot Glue: Hot glue creates a fast-setting bond that is ideal for quick projects. It works well with laminated paper due to its strong adhesion and ability to fill gaps, although it can become brittle over time and may not hold up under high heat.

- Spray Adhesives: Spray adhesives offer an even coating that can bond large surface areas effectively. They are particularly useful for projects requiring a smooth finish without visible glue lines, although proper ventilation is necessary when using them to avoid inhalation of fumes.

- Double-Sided Tape: This tape is easy to use and provides immediate adhesion without the mess of liquid adhesives. It is perfect for projects that require precision, as it allows for repositioning before the final bond sets, although it may not be as strong as liquid adhesives for heavy-duty applications.

- PVA Glue: Polyvinyl acetate (PVA) glue is a common choice for paper projects due to its flexibility and strong bonding properties. It dries clear and remains flexible after curing, making it ideal for laminated paper as it won’t crack or break the bond when the product is handled.

What Factors Should Be Considered When Selecting an Adhesive for Laminated Paper?

When selecting the best adhesive for laminated paper, several key factors should be taken into account to ensure optimal bonding and durability.

- Adhesive Type: Different types of adhesives, such as PVA (polyvinyl acetate), epoxy, or hot glue, have varying properties that can affect their suitability for laminated paper.

- Drying Time: The time it takes for the adhesive to dry can impact project timelines; some adhesives offer quick bonding, while others may require longer curing times.

- Flexibility: Adhesives should provide sufficient flexibility to accommodate the movement of laminated paper without cracking or breaking the bond.

- Water Resistance: Depending on the intended use, selecting an adhesive that is water-resistant can be crucial for preventing delamination in humid or wet conditions.

- Bond Strength: The adhesive’s bond strength is vital for ensuring the laminated paper remains intact, especially under stress or when exposed to varying temperatures.

- Application Method: Consideration of how the adhesive is applied, whether by brush, spray, or roller, can affect ease of use and the quality of the finished product.

- Surface Compatibility: The adhesive must be compatible with both the laminated paper and any additional materials used in the project to ensure effective adhesion.

The adhesive type is crucial because each type brings unique properties; for instance, PVA is great for craft projects, while epoxy offers stronger bonds for heavier applications. Drying time varies significantly, with some adhesives setting in minutes, making them preferable for quick projects, while others may take hours or even days for full strength. Flexibility is important because laminated paper may need to bend or flex without compromising the integrity of the bond, thus ensuring longevity in use.

Water resistance is key for projects exposed to moisture, as non-waterproof adhesives can fail over time in damp environments. The bond strength must be considered to ensure that the laminated paper can withstand handling and environmental changes without separating. The application method can influence not only the ease of use but also the uniformity of the adhesive layer, affecting the final appearance. Finally, surface compatibility ensures that the adhesive will effectively bond to the specific finishes and coatings present on the laminated paper, avoiding issues like peeling or bubbling.

How Do Adhesives Affect the Longevity of Laminated Paper?

The choice of adhesive plays a crucial role in determining the longevity and durability of laminated paper.

- PVA (Polyvinyl Acetate) Adhesives: PVA adhesives are popular for their strong bond and flexibility, making them suitable for various laminated applications. They dry clear and are water-based, which means they are easy to clean up but may not provide the best moisture resistance in humid environments.

- Epoxy Adhesives: Known for their exceptional strength and durability, epoxy adhesives create a very strong bond that can withstand harsh conditions. They are ideal for laminated paper that may be exposed to moisture or temperature fluctuations, although they require careful mixing and application.

- Hot Melt Adhesives: These adhesives are applied in a molten state and quickly solidify upon cooling, providing a fast and effective bond. They are particularly useful for high-speed production environments but can be less effective in extreme temperature conditions.

- Contact Adhesives: Contact adhesives create a strong bond when both surfaces are coated and allowed to dry before pressing them together. This type of adhesive is advantageous for laminated paper that requires an instant bond, although it may be difficult to reposition once the surfaces are joined.

- Polyurethane Adhesives: These adhesives are known for their versatility and excellent moisture resistance, making them suitable for outdoor laminated applications. They provide a strong bond that can endure a variety of environmental conditions but may require longer curing times compared to other adhesives.

What Common Mistakes Should You Avoid When Working with Laminated Paper Adhesives?

When working with laminated paper adhesives, it’s crucial to avoid certain common mistakes to ensure the best results.

- Using the Wrong Type of Adhesive: Selecting an adhesive that is not specifically designed for laminated surfaces can lead to poor adhesion and may cause the laminate to peel away over time. It’s important to use a water-resistant or waterproof adhesive that can withstand moisture without losing its bond.

- Applying Too Much Adhesive: Over-applying adhesive can create a mess and lead to uneven bonding. Excess adhesive may seep out from the edges, making the finished project look unprofessional and can also affect the drying time and strength of the bond.

- Ignoring Drying Time: Rushing the drying process can compromise the effectiveness of the adhesive. Each type of adhesive has specific drying and curing times, and failing to adhere to these can result in a weak bond and potential failure of the laminated project.

- Not Preparing the Surface Properly: Skipping surface preparation can lead to contaminants affecting the bond. Surfaces should be clean, dry, and free of dust or oils to ensure maximum adhesion between the laminate and the adhesive.

- Neglecting Temperature and Humidity Conditions: Working in inappropriate temperature or humidity levels can impact the performance of the adhesive. High humidity can prevent proper curing, while extremely low temperatures can make some adhesives less effective, so it’s vital to adhere to the manufacturer’s guidelines.